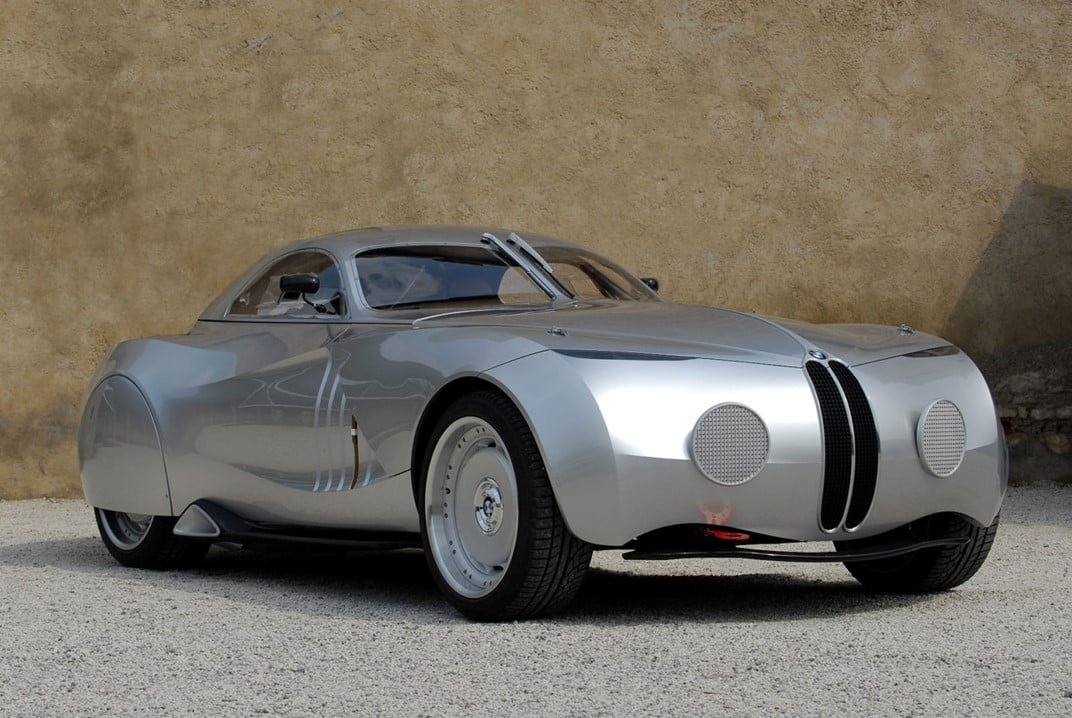

This was a one-off car designed to tribute the early race cars from the late 20’s to early 30’s that would race in the 1,000-mile race through Italy called the “Mile Miglia”. It now resides in the auto museum in Munich, Germany.

The whole concept of the car was vintage meets modern and asymmetry.

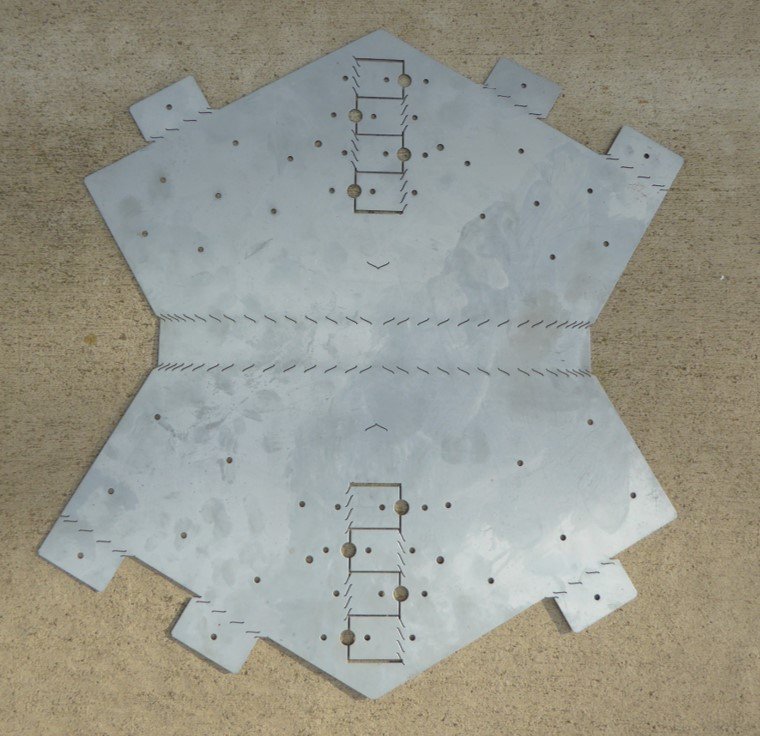

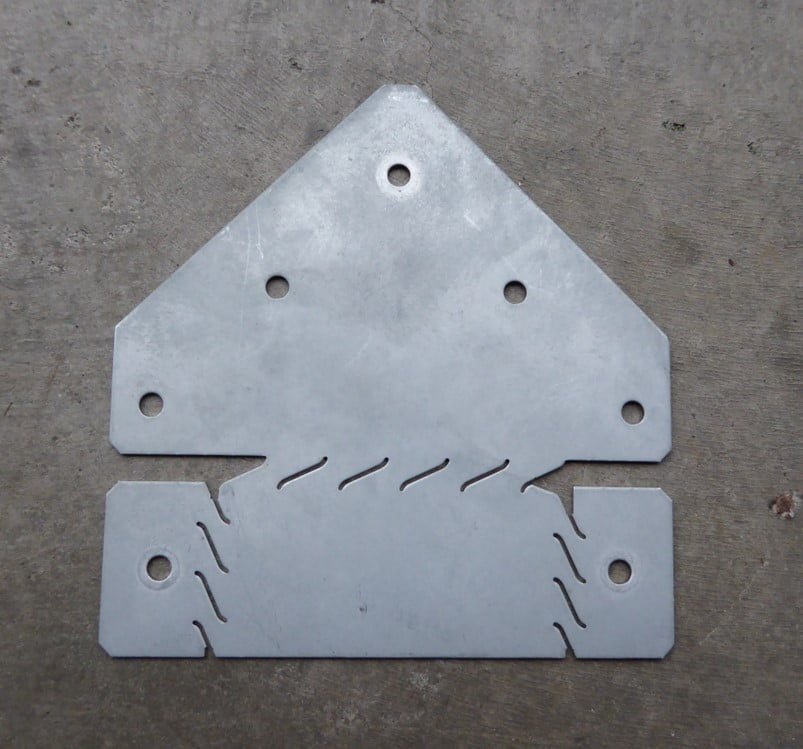

The interior, hand stitched leather on stainless steel.